Absolutely not. We leave our customers complete autonomy in the choice of whether or not to continue with Tournaire Equipment and its technological partners during this phase. Generally speaking, the customer remains free to choose the services that suit him for each phase of the innovation.

Industrialization

This last phase 4 of support towards the industrialization of your solution is based on the output data of the WiNatLab preliminary phases and more particularly of phase 3 with the industrial scale-up stage. The industrial scale-up allows to define the technology(ies) best suited to your needs for your innovation project. It also allows you to adjust your process and the associated operating conditions to optimize the transformation performance of the raw material, the yields obtained and the implementation parameters to be retained for the industrialization stage, depending on the level of research carried out on the platform.

These essential data will allow Tournaire Equipment’s teams to take over your project and accompany you in the budgeting phase. Then, the accompaniment continues towards the phase of pre-project study and detailed study to fix, with your teams, a precise elaboration of the CAPEX / OPEX in the spirit of a ”Total Cost of Ownership” (TCO) approach.

All the experience acquired for decades by Tournaire Equipment in the design and realization of turnkey industrial units will be at your service in this important phase of ‘time-to-market.

Continue with Tournaire Equipment

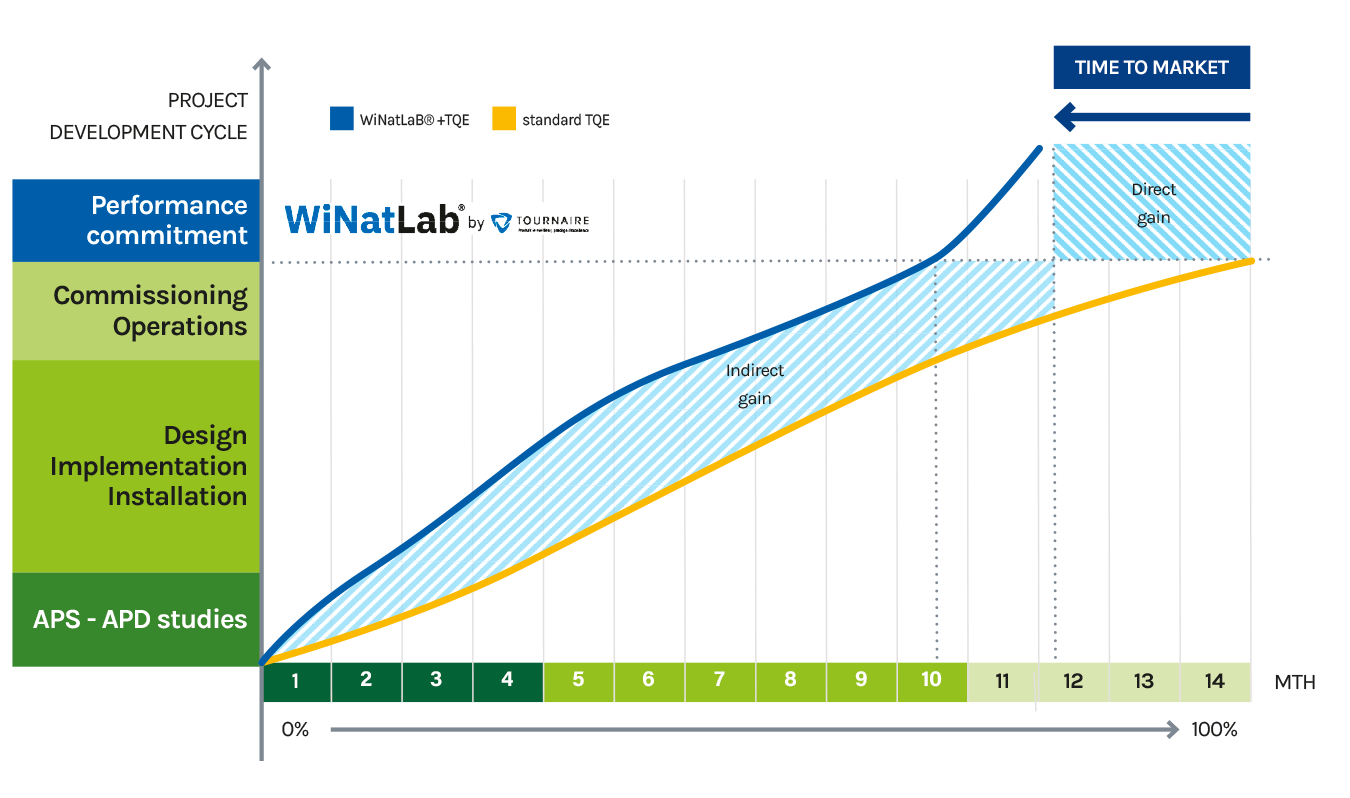

The graph above allows to visualize concretely the relevance of WiNatLab’s global support offer compared to a more conventional model, i.e.: via the constitution of a specification and the search for new service providers able to implement the solution validated at the end of phase 3.

For a project with an overall duration of 12 to 15 months on average, the reduction of the time-to-market is achieved by optimizing the implementation time of the preliminary design and final design studies. The time to market is also dependent on the duration of the industrial project, the gain of which can be evaluated at 2 – 3 months. Phase 4 therefore allows you to continue the process of accelerating your innovation project towards the market launch of your product.

Nowadays, the time saved represents a real financial saving on the overall cost and on the operation of a production unit.

The activation of this phase 4 of industrialization is directly linked to the level of maturity of your project and remains, of course, at your initiative according to the orientations you have chosen.

The support offered by WiNatLab, and in particular the results of the tests performed in phase 3, also allow to gather the necessary conditions to set up a performance commitment in relation with the future industrial unit.

Role of our partners

In phase 4, WiNatlab technological partners can be directly associated with Tournaire Equipment teams for the implementation of the industrial solution corresponding to the selected extraction technology. For example, an extraction unit using microwaves and ultrasounds, or supercritical CO2, will be realized with the collaboration of IDCO or Nova Extraction.

This synergy towards the implementation of your industrial solution is an additional asset for the success of the project and allows you to fully benefit from the work done upstream, in complete confidentiality.

This will allow us to benefit from the know-how of our partners and their industrial experience in applications related to natural products. In addition, Tournaire Equipment’s expertise in integrating the technology into a complete turnkey unit, including all utilities.

Frequently Asked Questions

-

Is the accompaniment on phase 4 of industrialization mandatory?

-

Is the accompaniment towards the industrialization solution systematically paying ?

No, because it is relatively easy, from the output data of phase 3, to elaborate a budgetary evaluation of the chosen solution on an industrial scale. On the other hand, Tournaire Equipment can then offer you support for the pre-project studies in order to evaluate more precisely the CAPEX investment amount.

-

What is the average duration of the implementation of an industrial turnkey solution ?

The duration varies according to the size of the investment and the amount of equipment to be designed and built. On average, in the case of a WiNatLab support, the average time will be between 8 and 12 months. In a more conventional context, 2 to 3 additional months can be added, mainly for the P&ID study and validation phase.

-

What are the main critical paths in an industrialization project?

A certain number of potential critical paths are dealt with upstream during phases 2 and 3. They are for example :

-

The choice of the most suitable technology

-

The definition of the specifications

-

Definition of the process parameters to obtain the expected performance

Then, in phase 4 of industrialization, the P&ID validation and implementation part are important elements to allow the equipment and the process to be fixed. These allow the detailed study phase to be initiated in order to launch the manufacture of the equipment. The FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) stages are key stages of the project and of the validation of the expected performances.

-

-

Can WiNatLab be a force of proposal to build the financing of an industrial project?

The aspects related to the financing of the project itself are not addressed here. These aspects must be dealt with upstream by our clients’ management bodies. Indeed, these aspects are out of WiNatLab’s and more generally Tournaire Equipement’s domain of competence.

Nevertheless, WiNatLab has a Research Tax Credit (RTC) approval allowing its customers to recover 30% of the research tax credit on the work done in phases 1, 2, and 3.

Finally, Tournaire Equipment has taken steps to obtain the support of the Southern Region for the development of WiNatLab. Tournaire has an excellent network of contacts in the region that can facilitate the search for financial assistance for the customers’ industrial projects.